| Availability: | |

|---|---|

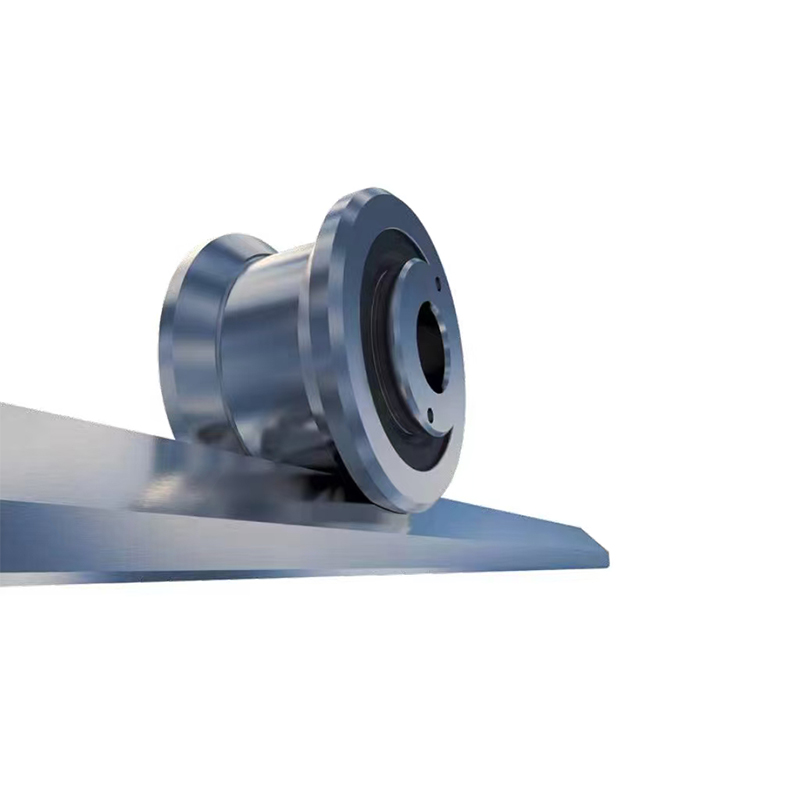

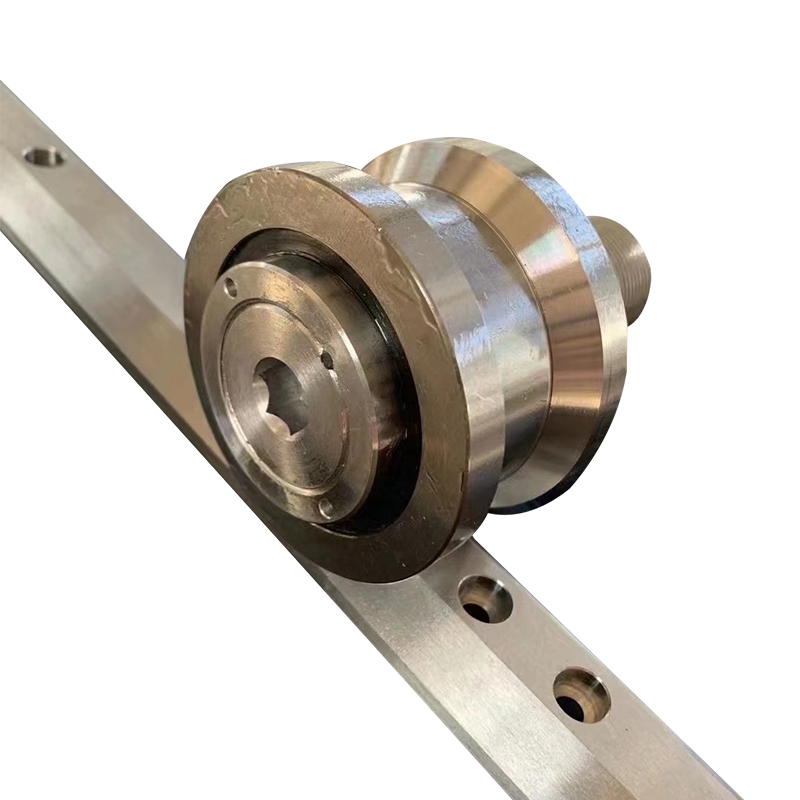

Advantages and Features

High precision and stability

The roller guide adopts precision machining technology to ensure high precision and stability during the movement process, suitable for high demand industrial applications.

Low friction and high speed

The rolling friction coefficient between the roller and the guide rail is low, which enables high-speed movement while reducing energy loss.

High load capacity

The roller guide rail design is sturdy and can withstand large radial and axial loads, making it suitable for heavy equipment.

Long lifespan and durability

Using high-quality materials and surface treatment technology, it has excellent wear resistance and corrosion resistance, extending its service life.

Easy to install and maintain

Simple structure, easy installation, low maintenance cost, suitable for various industrial environments.

Silent operation

The contact surface between the roller and the guide rail has been optimized for low noise during operation, making it suitable for noise sensitive environments.

Application scenarios

Automated equipment

Used for linear motion guidance of automated equipment such as robotic arms, conveyors, assembly lines, etc.

CNC machine tool

As a guiding component of CNC machine tools, it ensures machining accuracy and stability.

precision instrument

A guidance system suitable for high-precision instruments such as optical instruments and measuring equipment.

Logistics and Warehousing

Used for cargo conveying and sorting equipment in automated warehousing systems.

medical equipment

Applied to high-precision medical equipment such as medical imaging devices and surgical robots.

3D Printing and Laser Processing

As a motion guiding component for 3D printers and laser cutting machines, it ensures machining accuracy.

Instructions for Use

Pre-installation preparation

Check whether the surface of the guide rail and roller is clean, ensuring no impurities or damage.

Select the appropriate installation location and fixing method according to the equipment requirements.

Installation steps

Fix the guide rail on the equipment base to ensure levelness and straightness.

Install the roller assembly, adjust the pre tension to ensure even contact between the roller and the guide rail.

Check if the movement is smooth and there is no jamming phenomenon.

routine maintenance

Regularly clean the guide rails and rollers to remove dust and impurities.

Regularly lubricate according to usage to reduce friction and wear.

Check the wear of the rollers and guide rails, and replace damaged parts in a timely manner.

Common problems and solutions

Problem: Poor movement or jamming phenomenon

Reason: There are impurities or damage on the surface of the guide rail or roller.

Solution: Clean the guide rails and rollers, inspect and replace damaged parts.

Problem: Excessive noise during operation

Reason: Insufficient lubrication or excessive pre tension of the roller.

Solution: Add lubricating grease and adjust the pre tightening force of the roller.

Problem: Decreased accuracy

Reason: The guide rail or roller is severely worn.

Solution: Check for wear and replace the guide rail or roller if necessary.

Problem: Insufficient load capacity

Reason: Improper selection or unstable installation.

Solution: Re select or reinforce the installation.

content is empty!